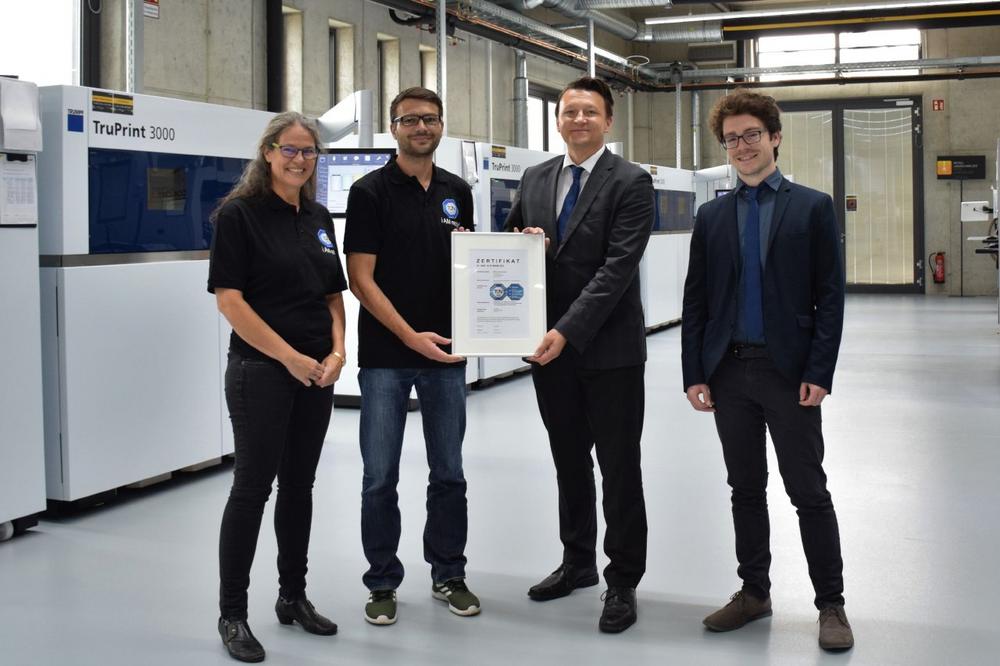

The ZEISS Semiconductor Manufacturing Technology (SMT) segment regularly evaluates its suppliers and awards prizes to those which come out on top. MBFZ toolcraft GmbH has recently received the coveted ZEISS SMT Supplier Award for the second time. In 2019, the […]